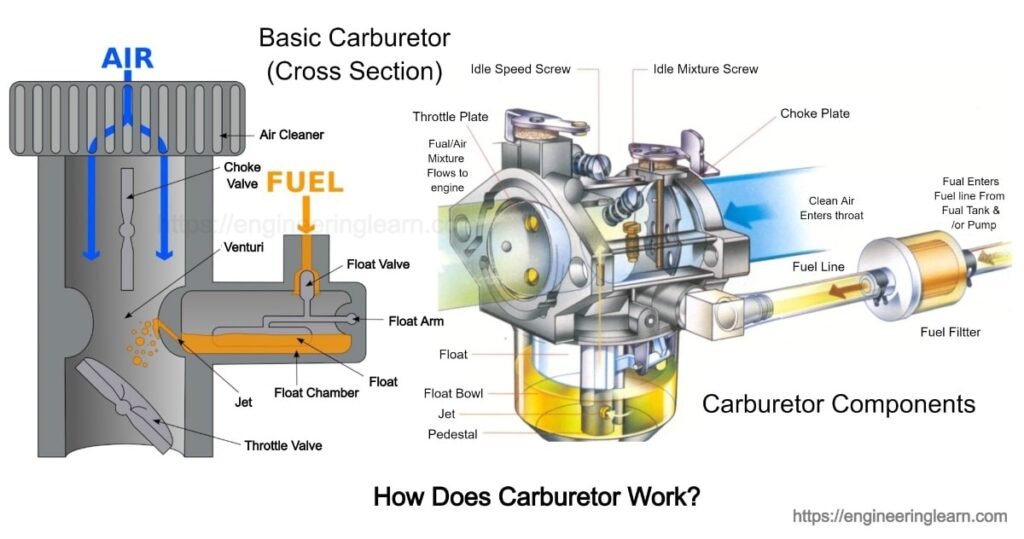

A carburetor is an essential component in small gasoline engines, responsible for mixing air and fuel in the correct ratio for combustion. This article will provide a detailed analysis of the carburetor’s structure, components, working principle, functions, selection criteria, and maintenance.

Carburetor Structure and Components

A carburetor consists of several key parts that work together to regulate the air-fuel mixture. The main components include:

- Air Cleaner: Filters incoming air to remove dust and debris.

- Choke Valve: Controls air intake to enrich the fuel mixture during cold starts.

- Venturi: A narrowing in the air passage that increases airflow speed and decreases pressure, helping draw fuel into the airstream.

- Float Chamber: Stores fuel at a constant level, supplying it to the jet as needed.

- Throttle Valve: Regulates the amount of air-fuel mixture entering the engine.

- Fuel Jet: A small nozzle that allows fuel to mix with air in the Venturi.

- Float and Float Arm: Maintain fuel level in the float chamber to ensure a steady supply.

- Idle Mixture Screw: Adjusts the air-fuel mixture at idle speed.

- Fuel Line and Filter: Transport and filter fuel before it reaches the carburetor.

How a Carburetor Works

The working principle of a carburetor is based on the Bernoulli principle, which describes how fast-moving air creates a pressure drop that draws fuel into the airstream. The process includes the following steps:

- Air Intake: Clean air enters through the air cleaner and flows into the carburetor.

- Choke Operation: During cold starts, the choke plate restricts airflow to create a richer fuel mixture.

- Venturi Effect: As air passes through the Venturi, its speed increases, reducing pressure and drawing fuel from the jet.

- Fuel Atomization: The fuel mixes with air and is atomized for efficient combustion.

- Throttle Control: The throttle plate adjusts the amount of air-fuel mixture entering the engine, controlling power output.

- Combustion: The mixture enters the engine cylinder, where it ignites to generate power.

Functions and Importance of a Carburetor

A carburetor plays a crucial role in engine performance, ensuring:

- Optimal air-fuel mixture for different operating conditions.

- Smooth acceleration and power delivery.

- Efficient fuel consumption and reduced emissions.

Selecting the Right Carburetor

Choosing the right carburetor for an engine depends on several factors:

- Engine Size and Application: Different engines require specific carburetor sizes and designs.

- Air-Fuel Ratio Requirements: Depending on performance needs, different jets and air-fuel mixture settings may be necessary.

- OEM vs. Aftermarket: OEM carburetors ensure compatibility, while aftermarket options may offer custom performance tuning.

-

SP-CP19 Carburetor for Micro Tiller & Water Pump 168-225CC 3-5KW$10.00

-

SP-27B-1 Carburetor for Micro Tiller & Water Pump 300-457CC 6-8.5KW

-

SP-19C Carburetor for Micro Tiller & Water Pump 168-225CC 3-5KW

-

SP-18-2 Carburetor for Lawn Mower 120-225CC 2-4.5KW

-

SP-27-1 Carburetor for Lawn Mower 250-457CC 5-8KW

-

SP-18-1 Carburetor for Lawn Mower 120-225CC 2-4.5KW

-

SP-29B Carburetor for Cleaning Machine 500-550CC 9.5-10KW

-

SP-27B Carburetor for Cleaning Machine 300-457CC 6-8.3KW

-

SP-23B Carburetor for Cleaning Machine 270-300CC 5.5-6KW

Types of Carburetors

Carburetors are essential components in internal combustion engines, mixing air and fuel for efficient combustion. They come in various designs, each suited for specific applications and engine requirements. Here are the main types of carburetors:

1. Updraft Carburetor

- Air enters from the bottom and moves upward into the engine.

- Commonly used in older engines and small industrial applications.

2. Downdraft Carburetor

- Air flows downward due to gravity and engine suction.

- Typically found in automobiles and small gasoline engines.

3. Horizontal Carburetor

- Air and fuel flow horizontally into the engine.

- Used in motorcycles, small engines, and racing applications.

4. Natural Draft Carburetor

- A variation of the horizontal carburetor with minimal air resistance.

- Often used in small power equipment.

5. Single Barrel Carburetor

- Features one air and fuel mixing chamber (barrel).

- Suitable for low-power engines like motorcycles and small vehicles.

6. Dual Barrel Carburetor

- Contains two barrels for improved fuel delivery.

- Used in mid-range performance engines.

7. Four-Barrel Carburetor

- Has four separate barrels, enhancing power and efficiency.

- Commonly found in high-performance and V8 engines.

8. Constant Choke Carburetor

- Maintains a fixed choke opening while varying fuel supply.

- Used in simple and small engine designs.

9. Constant Vacuum (Variable Venturi) Carburetor

- Adjusts the venturi size based on engine demand for optimal air-fuel mixture.

- Seen in some motorcycles and older vehicles (e.g., SU carburetors).

10. Multiple Carburetor System

- Uses multiple carburetors for high-performance applications.

- Common in racing engines and classic sports cars.

Each type of carburetor has its advantages, with design choices depending on engine performance needs, efficiency, and application requirements.

Maintenance and Care

Regular maintenance is essential to ensure a carburetor functions optimally. Key maintenance practices include:

- Cleaning the air filter and jets to prevent clogging.

- Checking the fuel filter and replacing it periodically.

- Adjusting the idle mixture and throttle settings for smooth performance.

- Inspecting for leaks and worn-out components.

About Chinasmallengines.com

Chinasmallengines.com is a leading platform specializing in small engine components, leveraging China’s robust small engine industry. The website offers a wide range of OEM and ODM carburetor manufacturing services, ensuring high-quality products for various applications, including generators, water pumps, and agricultural equipment. With expertise in carburetor production, Chinasmallengines.com provides reliable solutions to meet global industry demands.

For more details on high-quality carburetor solutions, visit Chinasmallengines.com.